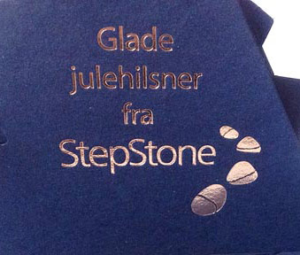

If you see printed material that has a mirror-like metallic imprint on it, it’s likely that you’re looking at the printing process known as ‘foiling’. Foiling really gives your printed items an added ‘wow’ factor — any foiled areas will catch the light in a way that other printing processes simply cannot accomplish. Foiling is a great way to set your printing apart from that of your competitors, giving it an extra dimension and almost jewel-like detailing. Foiled areas will glint in the light and give your printed pieces a feel of real quality.

Digital foiling is one of several new services that are now available at Southside Print, courtesy of our Vivid Matrix 530D digital foiling facility. While hot foiling is always available, the new digital foil service offers several benefits over its more traditional counterpart. Here we’ll take a look at the differences, benefits and any limitations of each process.

Similarities

- Both processes can accomplish an attractive metallic printed finish to logos, text and graphics, as desired.

- Both processes offer a variety of finishes including a mirror-like shine or more muted satin and matt effects.

- Both processes offer a variety of colours including anything from the traditional metal colours like silver, gold, rose gold, and copper to more standard colours like blue, green, red, pink and white.

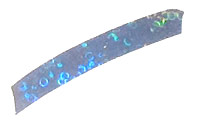

- Both processes can also accomplish holographic effects within the metallic coating. These are rather like you might find on a banknote or high quality voucher.

- Both processes can also replicate spot varnish effects through the use of clear foils. However, for those looking for the ultimate in high gloss, real U.V. varnishing will accomplish a much higher gloss than is possible using foils.

Digital Foiling

Digital Foiling

- Digital foiling requires no ‘die’ (a bespoke metal stamping block) but requires an additional printing pass compared to traditional hot foiling.

- Digital printing can be accomplished almost instantly, whereas traditional hot foiling requires a larger amount of set-up.

- Fine detail is possible with both types of foiling, however finer detail can be held using digital foiling.

- Because it is not indented (indeed it may even be very slightly raised), digital foil may not catch the light and glint quite so much as the hot foil process, which is stamped hard into the paper or card, causing the indent. However, it’s only a subtle difference.

- Supplying a one-off foiled printer’s proof is totally viable with digital printing. With traditional hot foil it would usually be cost-prohibitive on all but the highest budget jobs.

- Digital foiling is accomplished entirely in-house, so usually offers speed and cost savings over traditional hot foil, being particularly cost-effective for short to medium volumes of printing.

- While digital foiling can accomplish holographic effects, they are limited to just a few

options including glitter and rainbow patterns. Unlike with traditional hot foiling, it is not usually possible to have bespoke holographic effects with digital foiling, which is limited to off-the-shelf holographic patterns.

options including glitter and rainbow patterns. Unlike with traditional hot foiling, it is not usually possible to have bespoke holographic effects with digital foiling, which is limited to off-the-shelf holographic patterns. - The digital foiling process can use special foils that are printable, meaning that you can print black or coloured graphics over the top of the foiled areas. That is particularly useful if you want the entire background of your job to be foil (e.g. glitter foil) with graphics printed on top of the metallic surface, for example on product packaging.

- If your job requires foiling on top of an area already printed with ink, it will have to be laminated first (unlike with traditional hot foil). However, this is not always the case, for example if the printed ink doesn’t meet the foiled area and if the job is printed in a particular order.

Traditional Hot Foil

Traditional Hot Foil

- Traditional hot foiling requires a metal die, which costs more the larger it is. This die is heated and pressed into the paper under high pressure so as to make the foiling film adhere to the paper or card.

- The pressure used during the hot foil process causes the underlying paper or card to become indented/debossed. This can be quite attractive, in fact, as it can cause the foiled area to glint and catch the light more readily.

- While both digital and traditional hot foiling techniques can ‘print’ in a variety of metals, colours and finishes, traditional foiling has a wider range available.

- Traditional hot foiling can use totally bespoke holographic effects e.g. you might want your logo to appear in the holographic ‘image’. As well as adding a unique and attractive feel to the printed piece, such bespoke holograms are also used as security devices because they are harder to copy. However, the added cost needs to be factored in.

- Unlike with digital foiling, you never need to laminate your sheets if you don’t want to. Foiling can take place on top of any printed ink when you use the traditional hot foiling process.

- Although more expensive than digital foiling for small and medium print quantities, traditional hot foil can save money for particularly large print volumes.

Using Foiling in your Printing

Foiling adds a high quality feel to key details on printed pieces like packaging, stationery, business cards, annual reports, brochures, book covers and wedding stationery and is also a perfect addition for security detailing and top-end bespoke design work. Foiled jobs automatically sell themselves as high quality sales or marketing pieces — almost effortlessly. So if you’re looking to stand out from the crowd and add quality to your brand, we can thoroughly recommend metallic foiling as an option.

If you decide to go ahead, ask us how best to supply your artwork (hint: a separate ‘spot colour’ separation usually does the trick) or we can produce it for you if you prefer. Quotations are free and without obligation at Southside Print. Our digital foiling press can foil up to SRA3 (320mm x 450mm) in one pass so that’s large enough for the vast majority of jobs. Our in-house digital foiling service allows us to foil multiple areas across the flat sheet, without the need for an expensive die (metal printing block) and even means that you can have the background printed in foil, edge to edge if you like.

Southside Print is based in Tabard Street, SE1, close to London Bridge and Borough stations. So, we’re conveniently located for a huge number of businesses, shops and organisations in London SE1. However, we also offer our design and printing services to other South and Central London locations including The City, Shoreditch, Victoria, Clerkenwell, Canary Wharf and Farringdon — anywhere in London in fact. What’s more, we’ll soon be launching a full e-commerce section on our website where anyone – anywhere – will be able to buy our high quality, low priced printing online — so watch this space! Call 020 7378 6754 for further details, request a printing or design quotation here or email us a message here and we’ll be happy to help. You can also send us your finished artwork here if you’re ready to go ahead right away.

About Mark at Pilot

Mark helps companies market themselves online, through search-engine-friendly copywriting, search engine optimisation (SEO) and content writing for websites, blogs and social media. This radically improves search engine rankings and increases qualified traffic and enquiry levels for any business. Other creative services include high quality graphic design and the design and build of responsive websites. We also specialise in social media marketing (SMM) and the management of pay-per-click advertising campaigns including Google Ads.

Learn MoreMore Articles

London Artists Unite to Support Ukrainian Families

Earlier in March, Southside Print was approached by a professional musician named Emilija. This amazing…

An Urgent Printing Service in London

Do you have an urgent printing job that simply MUST be turned around super-fast? If so, Southside…

Top Tips for Printing on a Budget

Sometimes a printed sales or marketing job simply needs to be as economical as possible. The quality…

Digital Foiling

Digital Foiling options including glitter and rainbow patterns. Unlike with traditional hot foiling, it is not usually possible to have bespoke holographic effects with digital foiling, which is limited to off-the-shelf holographic patterns.

options including glitter and rainbow patterns. Unlike with traditional hot foiling, it is not usually possible to have bespoke holographic effects with digital foiling, which is limited to off-the-shelf holographic patterns. Traditional Hot Foil

Traditional Hot Foil